Acoustic solutions for industrial equipment failures

Acoustic monitoring-based solutions provide the industry with a non-contact technological approach. As a provider of acoustic monitoring solutions focused on the industrial sector, Ensonic Technology has developed a series of products that are suitable for the vast majority of rotating or reciprocating machine motion scenarios. These products can diagnose and analyze common mechanical faults, providing core support for applications such as predictive maintenance, quality inspection, and pattern matching.

Overview

Background

Real-time monitoring of the operational status of large industrial equipment is crucial for preventing accidents in modern production. With the development of big data and artificial intelligence technologies, predictive maintenance has also become an important component of Industry 4.0 and Made in China 2025. Traditional monitoring solutions such as infrared monitoring, ultrasonic monitoring, vibration monitoring, and thermal monitoring have significant drawbacks, such as the need for pre-installation before the equipment leaves the factory or the need for retrofitting the equipment later, resulting in high deployment costs, time costs, and decision-making costs.

Program Value

Acoustic monitoring-based solutions provide the industry with a non-contact technological approach. As a provider of acoustic monitoring solutions focused on the industrial sector, Ensonic Technology has developed a series of products that are suitable for the vast majority of rotating or reciprocating machine motion scenarios. These products can diagnose and analyze common mechanical faults, providing core support for applications such as predictive maintenance, quality inspection, and pattern matching.

High accuracy and timeliness

Voiceprint recognition technology can accurately identify and distinguish between normal and abnormal voiceprint features. Once an abnormal voiceprint is detected, the system can automatically trigger an early warning mechanism to promptly notify maintenance personnel for handling.

Real-time capability and early warning ability

The voiceprint monitoring system can capture subtle acoustic changes in real-time during device operation and quickly identify abnormal voiceprints through intelligent analysis algorithms.

Non-contact and flexibility

Voiceprint monitoring technology collects and analyzes voiceprint signals through microphone sensors and data acquisition devices, featuring flexible sensor arrangement, simple devices, and minimal impact on equipment.

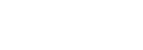

Architecture Diagram

Choose the right product for you

Contact Us

You can contact Disheng by phone at:4000-999-868; or for consultation needs, feel free to leave us a message at any time.